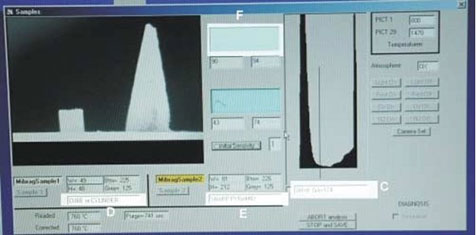

Uses the Latest technology in the service of the fusion temperature determinations Sylab Scientific Ash Fusion Analyzer automatically determines four critical temperatures: Deformation Temperature, Softening temperature, Hemispherical Temperature and Fluid Temperatures. It is a Fully automatic instrument for determining the Ash Fusion points by means of Image analysis. Sylab Scientific’s Ash fusion analyzer uses modern technology for monitoring, computing, and storing results and curves obtained during the test. Up to 6 samples can be analysed in each batch.

AFT is available in multiple models based on the application and samples

We can offer CRMs which are compatible with our AFT, from world-renowned manufacturers. Please do contact us for further information

During combustion of samples like Coal, Coke, Biomass and Refuse derived fuel, the remaining non-combustible material becomes ash or liquid slag. Ash Fusion Analyzers are used to determine ash cone deformation temperatures. The ash cones change shape in response to increasing heat. Temperatures are recorded for different stages in the shape changes, which, in order of increasing heat, are called : Initial deformation temperature (IT), Softening temperature (ST), Hemispherical Temperature (HT) and Fluid Temperature (FT). The behaviour of the Ash residue at high temperatures is a critical factor in selecting the suitable fuel for boilers and furnaces.

Ash Fusion temperature is measured at 4 points or stages of heating, by observation of the behaviour of triangular Pyramids, Cones, Cylinders prepared from ash when heated at a specific rate in a controlled atmosphere.

The Ash Fusion Analyzer determines the behaviour of fuel ash in combustion, gasification, liquefaction and ash utilization. The characteristics of fuel ash for its tendency to slag and foul have been traditionally related to the bulk chemistry of the ash and ash fusion temperatures. It can cause slagging or clogging problems on combustion chamber and pipe surfaces and decline heat transfer efficiency. It is said that the operating temperature should be below the fluid temperature (FT). Thus, it is necessary to study the Ash Fusion Analyzer not only theoretically, but also for practical application.

The Higher the fusion temperatures of the fuel-ash, the lower the tendency of the ash to slag in the combustion chamber of boilers.

Ash Fusion temperatures are often cited in fuel specifications for boilers, because they are believed to be a measure of the tendency of Coal Ash to form clinkers.

| Ash Fusibility Determination | Automatic |

| Fusion Points | IT (Initial deformation Temperature),

ST (Softening Temperature), HT (Hemisphere Temperature) & FT (Fluid/Flow Temperature) |

| Maximum Samples per Analysis | Up to 6 samples can be analysed in each batch. |

| Test Method | IF2000G-HDC complies with ISO 540, ASTM D 1857, CEN/TS 15370-1, CEN/TR 15404. |

| Analysis Time | 3 runs per working day |

| Capable to Analyse | Cube Cylinder, Truncated Pyramid and Upright Pyramid |

| Analysis atmosphere | Oxidizing Atmosphere/Reducing atmosphere |

| Sample shape identification | Pyramid, Truncated Cone, Pyramid, Cylinder and Truncated Pyramids are Automatically Identify |

| Operating Furnace Temperature Range | up to 1600 deg C |

| Maximum Furnace Temperature Range | up to 1600 deg C |

| Temperature Ramp Rate | Programmable 1 deg C to 12 deg C per minute |

| Heating elements | Silicon carbide |

| Operating Condition | 15 deg C to 35 deg C 20% to 80%, non-condensing. |

| Safety | Integrated CO monitor with auditory alarm, gas flow stops on alarm |

| Ash Fusibility Determination | Automatic |

| Fusion Points | IT (Initial Deformation Temperature),

ST (Softening Temperature), HT (Hemisphere Temperature) & FT (Fluid/Flow Temperature) |

| Maximum Samples per Analysis | Up to 6 samples can be analysed in each batch. |

| Test Method | IF2000G-HD/IF2000G-HDBM complies with ISO 540, ASTM D 1857, CEN/TS 15370-1, CEN/TR 15404. |

| Analysis Time | 3 runs per working day |

| Capable to Analyse | Cylinder, Cube, Pyramid, Truncated Pyramid Upright Pyramid |

| Analysis atmosphere | Oxidizing Atmosphere/Reducing atmosphere |

| Sample shape identification | Automatic, Pyramid, Truncated Cone, Pyramid and Cylinder |

| Temperature range | up to 17050 deg C |

| Maximum Furnace Temperature | up to 1600 deg C |

| Temperature Ramp Rate | programmable 1 deg C to 12 deg C per minute |

| Heating elements | Lanthanum Chromite |

| Operating Condition | 15 deg C to 35 deg C 20% to 80%, non-condensing. |

| Safety | Integrated CO monitor with auditory alarm, gas flow stops on alarm |