What is a Jaw Crusher?

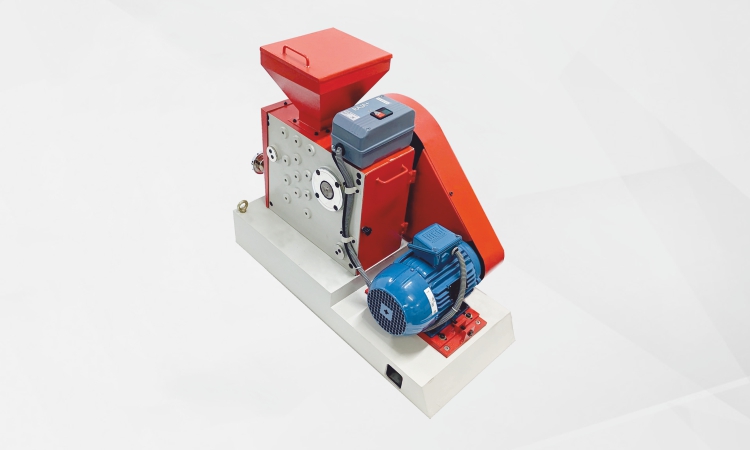

A jaw crusher is a powerful mechanical device designed to break down hard and bulky materials into smaller, manageable pieces. Whether it's used deep in a mine, at a construction site, in a testing lab, or for recycling metal scraps, this equipment has earned its reputation as a reliable first-stage crusher for solid materials. At Sylab Scientific, our jaw crushers are built for strength, precision, and durability - making them the ideal choice for laboratories, mining operations, and material testing applications.

How a Jaw Crusher Works

A jaw crusher works on a simple yet effective principle - compression. Material is crushed between two hard surfaces until it fractures into smaller pieces.

Step-by-Step Process

- Feeding the Material

Large chunks of material are fed into the crusher through a hopper.

- Crushing Action

Inside the crushing chamber, two jaws perform the main action:

- Fixed Jaw - stationary plate.

- Moving Jaw - reciprocates back and forth.

Powered by an eccentric shaft and motor, the moving jaw compresses material against the fixed jaw, gradually breaking it down into smaller fragments.

Discharge

Once the material is small enough to pass through the bottom opening (called the discharge gap), it exits the crusher - ready for further processing or testing.

Types of Jaw Crushers

Selecting the right type depends on your material hardness, required output, and operational needs.

- Single Toggle Jaw Crusher

- Operates with one moving jaw powered by an eccentric shaft.

- Simpler design with fewer parts - ideal for medium-duty crushing.

- Suitable for laboratories and smaller industrial setups.

- Double Toggle Jaw Crusher

- Uses two toggles and two shafts for greater crushing force.

- Handles harder materials and heavy-duty applications.

- Common in mining and large-scale processing plants.

Key Features of a Jaw Crusher

- High Crushing Capacity: Handles large volumes of hard material with ease.

- Adjustable Output Size: Control the discharge gap for precise particle sizing.

- Durable Design: Built from high-strength steel or cast iron for long life.

- Low Operational Cost: Simple mechanics mean less maintenance.

- Compact Models Available: Perfect for both lab-scale and industrial use.

Applications of Jaw Crushers

Jaw crushers are used across a variety of industries for crushing and sample preparation:- Mining & Metallurgy: Breaking ores for mineral separation.

- Construction & Demolition: Crushing concrete, rubble, and aggregates.

- Laboratories: Preparing solid samples for analysis.

- Recycling Plants: Reducing metal scraps and industrial waste.

- Ceramic & Glass Industry: Crushing raw materials before processing.

Why Every Lab Needs a Jaw Crusher

In any materials testing or research laboratory, a jaw crusher is an indispensable piece of sample preparation equipment. Here's why:

- Starts with the Right Size

Before chemical testing or mineral analysis, samples must be uniform in size. Jaw crushers turn large, irregular chunks into consistent, smaller pieces - ensuring accuracy in every test.

- Built Tough for Real-World Samples

Designed to crush hard, abrasive materials like granite, quartz, slag, or concrete. Durable steel jaws and frames withstand heavy use without compromising performance.

- Precision & Accuracy

A well-prepared sample ensures reliable analytical results. Jaw crushers help create representative samples that lead to better data and confident decision-making.

- Time & Effort Efficiency

Manual crushing is inconsistent and labor-intensive. Jaw crushers automate the process - saving time and improving lab efficiency.

- Versatile Applications

Ideal for research, quality control, and educational laboratories. Suitable for a wide range of materials and testing requirements.

Maintenance Tips

Extend your jaw crusher's lifespan and ensure consistent performance with these best practices:

- "Clean regularly after use to prevent residue build-up.

- Inspect jaws and bearings for wear or damage.

- Lubricate moving parts as recommended by the manufacturer.

- Keep the discharge gap calibrated for accurate output.

- Store in a dry, dust-free environment when not in use.

Common Jaw Crusher Issues & Fixes

| Issue | Possible Cause | Solution |

Uneven Output Size |

Improper gap setting |

Adjust discharge gap |

Excessive Vibration |

Loose bolts or worn bearings |

Tighten or replace parts |

Overheating |

Poor lubrication |

Re-lubricate and check oil levels |

Material Build-Up |

Sticky materials or wet feed |

Clean regularly and control moisture |

Conclusion

A jaw crusher is more than just a machine - it's the foundation of effective material processing and accurate laboratory testing. By choosing the right model, maintaining it properly, and understanding how it works, you can ensure precise results and long-lasting performance.

For ISO-certified jaw crushers and material testing equipment, contact Sylab Scientific - your trusted partner in laboratory precision and reliability.