Sylab’s TGA 3000 is an automated instrument which determines Moisture content, Ash content, Volatile content, Loss on Ignition (LOI) and Fixed Carbon content in a wide range of Organic, Inorganic and Synthetic materials. Thermogravimetric analysis replaces the traditional analytical techniques that are slow, labor intensive and involve several steps with multiple laboratory equipment such as muffle furnaces, ovens and balances. The TGA 3000 with integrated balance combines drying, ashing and weighing processes. This improves the efficiency, precision and provides high sample throughput. The TGA 3000 is applicable in various industries and applications, including coal, coke, ores, cement, lime, foodstuffs, feeds and many more.

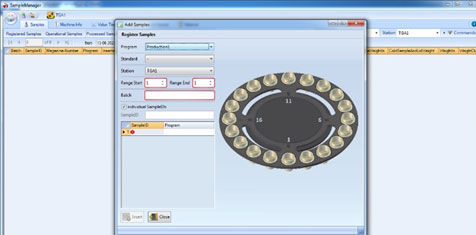

19 position carousel allows for high sample throughput rates. Two TGA 3000’s can be controlled from a single PC, thereby boosting productivity and reducing costs

Once the analysis is complete, the cooling process automatically starts with the user-programmable opening of the furnace to improve cooling time.

The pneumatic carousel control mechanism increases long-term reliability by eliminating oscillation and increasing position accuracy. Automatic control of the furnace atmosphere and programmable gas flow rates (air, nitrogen or oxygen).

High-power heating elements provide rapid temperature rise and excellent stability. The integrated multi-element design ensures that temperatures are uniform throughout the furnace chamber.

Single carousel for holding crucibles with manual handling of crucible covers, automatic end point recognition, user programmable method parameters as well as skipping of empty crucibles to optimize analysis time.

Balance isolated from heat and ambient atmosphere for stable and precise measurements. Scale accurate to 0.1 mg for high precision weight measurements.

TGA 3000 is not available for sale in USA.

TGA is available is multiple configurations based on the application and samples

Insulated balance that is isolated from the heat and ambient atmosphere for stable and precise measurements. High precision balance accurate to 0.1mg for precise weight measurements.

We can offer CRMs compatible with our TGA, from world-renowned manufacturers. Please do contact us for further information

In TGA 3000 Thermogravimetric analyzer, the mass of samples in a controlled atmosphere is recorded repeatedly as a function of temperature or time or both. In TGA 3000 Thermogravimetric Analyzer, the sample size is approximately 1 gram (or up to 5 grams) is used for most of the samples. All mass measurements are conducted by the system. In a typical analysis, the temperature is normally ramped from ambient to a specific temperature and held at that temperature for a prescribed length of time. The mass change is recorded repeatedly during the entire procedure. The thermogravimetric analysis of the sample is complete when the sample reaches a constant mass as defined in the instrumental operating parameters. Alternatively, the measurement can be considered complete after heating the sample for a fixed period of time.

The TGA 3000 consists of a computer and a multiple sample furnace that allows up to 19 samples to be analysed simultaneously.

A suitable analysis method/ test method can be selected from the software. After selecting the test method, empty crucibles and Crucible covers are loaded into the furnace carousels. The analysis method controls the carousel’s movement, furnace, and balance operation. On completion of crucible and Crucible Covers tare, each crucible is presented to the operator for sample loading. The starting sample weight is measured and stored automatically. Once all the crucibles have been loaded, the analysis begins. The weight loss of each sample is monitored, and the furnace temperature is controlled according to the selected analysis method. The percent weight loss for each sample is reported at the end of each analysis step.

Key to the automated analysis capability is the TGA 3000 multiple sample furnace. The 19-position sample carousel and balance pedestal are located in the furnace. The samples are automatically indexed to the position above the balance pan. The carousel is lowered to place a sample crucible onto the pedestal and the weight is recorded. The cycle continues throughout the entire program. All weighing is performed automatically.

| Temperature | Ambient to 1100 °C |

| Accuracy of Temperature Control | ±2% (or) ±2 °C |

| Ramp Rate | 10 °C /minute to 50 °C /minute |

| Balance | Integrated Balance |

| Resolution | 0.0001g (0.1mg) |

| Sample Size | up to 5 grams (Higher range can be offered on request) |

| Number of Samples | 19 Samples +1 Reference |

| Number of Carousels | Two (one for Crucibles, Crucible Covers) |

| Carousel Material | High temperature heat resistant engineering grade material |

| Precision | 0.02% RSD (on inert Samples) |

| Power Supply | 230V AC ± 10%; 50/60Hz/32A |